Read:

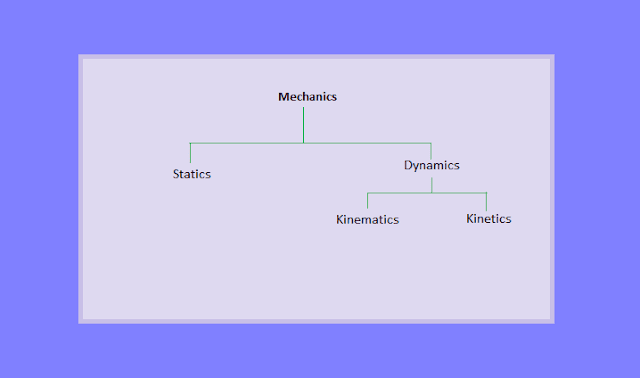

What is a Clutch? - Types of Clutches

Consider a plate or

disc clutch

Let

I

A = mass moment inertia of rotors attached to shaft A

I

B = mass moment inertia of rotors attached to shaft B

ω

A = Angular speed of shat A before engagement

ω

B = Angular speed of shat B before engagement

ω = Common angular speed of shat A and Shaft B after engagement

According to the principle of conservation of momentum, Total momentum before clutch engage is equal to the total momentum of the clutch after clutch disc engagement.

IA ω

A + IB ω

B = (I

A + I

B)ω

Common angular speed after engagement of clutch pressure plate

Total Kinetic energy before

friction clutch engagement

Kinetic energy after clutch engagement

Put the value of ω into above equation,

Now the loss of energy during clutch engagement, E= E

1-E

2

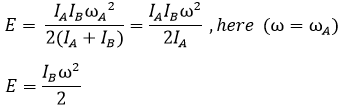

Apply Different condition for above equation

Condition I - The rotor attached and hence the shaft B at rest ω

B = 0

Put these condition in equation (a), and equation (b) we get

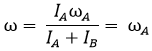

Common angular speed after the clutch engagement,

Loss of kinetic energy

Condition II - If rotor B at rest (ω

B = 0) and I

B is very small when compared to I

A

Common angular speed after the clutch engagement,

Kinetic energy loss,

.png)