Broaching Operation and Elements of Broaching Tool

What is broaching?

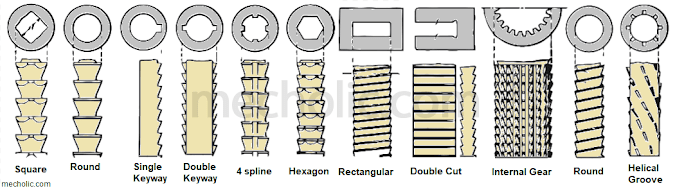

Broaching is a metal cutting operation using a toothed tool known as broach. There is two type of broaching, linear broaching and rotary broaching. In linear broaching, broach run linearly against the workpiece. In rotary broaching, the broach is rotated (using lathe and screw machine) and then pressed against the workpiece to cut predetermined shape. The broaching further classified into internal, external, push, pull, vertical, horizontal etc. following figure shows the common internal cutting using broach.The common material used for broach is high-speed steel. Carbide broaches are used for broaching of harder material like cast iron. TiN (Titanium nitride) coated carbide tool is used for longer tool life.

Tool geometry/ Nomenclature of broaching tool

Broach/ broaching tool is a multiple toothed tool made in the form of rods and bars. Teeth are arranged similar to saw, except varying teeth height over the length of tool. The height of each tooth determines material removal by the tooth. The series of multiple tooth is arranged in three distinct sections known as roughing teeth, semi-finishing teeth, and finishing teeth. Following figure shows the elements of a broach.Roughing teeth are the designed to do the rough cutting, it removes the bulk of material. The semi-finishing teeth remove small amount of material when compared to rough cutting teeth. It is followed by finishing teeth for finishing operation, and removes very little material.

Pull end: Engaging broach in machines.

Neck: this short part has diameter lower than the other parts. Which is where the tool allowed to fail in case of overloading.

Front pilot and Rear pilot: parts helps in locating and resting of tool.

Teeth: cutting of material takes place here.

The progressive teeth take of the successive layer from workpiece, and large amount of material will be removed by a single pass.

The pitch of broach determines the length of cut and chip thickness which broach can handle. While the land of tooth determines the strength of tool. The rake angles of teeth is depending on the material to be cut. Each broach is designed to do a specific machining operation (unique dimension, geometry, etc.)