Self Tapping Screws and Non-Self-Tapping Screws Classification Applications Advantages and Limitations

What are Self Tapping Screws

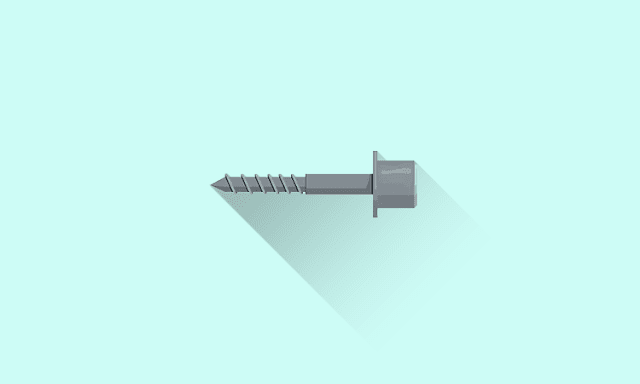

Self-tapping screws are specifically made to cut their own thread path as they're being inserted, without the need for a tap before insertion. Sometimes, the screw will have axial grooves in some threads to give them a cutting edge. This means that self-tapping screws do not require a pre-drilled hole, making them a popular choice for DIY projects and other applications where speed and convenience are a priority. These screws stand out due to their unique tip shape and design, differentiating them from other screws.

These screws usually come with a tip featuring cutting flutes that aid leading threads to cut a path. However, since the flutes are located only at the tip and not extended to the entire screw length, any debris formed during the process cannot be removed entirely and is instead pressed into the thread path.

🔗What is screw? Parts of screw

🔗Types of Screws Based on Their Applications

The installation process for self-tapping screws is rapid and straightforward, requiring only a drilled or moulded pilot hole. These screws are popular due to their impressive holding force and lower stress production than other fastening techniques. They have a pull-out strength similar to that of moulded-in threaded metal inserts. If assembled correctly, self-tapping screws display a similar tendency to threaded metal inserts for stress cracking. However, an incorrect assembly can cause damage to the threads.

Self-tapping screws come in a wide variety of tip and thread patterns and can be available in nearly any screw head design. These screws typically feature threads covering the entire length from the tip to the head and a well-defined thread that is hard enough to handle the intended substrate. Thread is commonly made case-hardened.

Applications of Self-Tapping Screws

Selecting the appropriate self-tapping screw requires careful consideration of the material on which it will be used. Different kinds of self tapping screws have been designed for use on different kinds of materials, such as wood, metal, or plastic. The size and length of the screw are crucial factors to consider. Additionally, the required torque needed for the application should also be taken into account.

Self-tapping screws have diverse applications, ranging from DIY carpentry to surgery. They are widely used in bone surgery as they allow quick insertion, reducing the operation time for internal fixation. In the medical field, self-tapping screws are frequently utilized in dental implantation and orthopaedic bone fixation. The thread is cut by the screw itself, resulting in a tight fit of the screw thread in the bone. Different types of profiles are used for denser cortical bone or spongy cancellous bone. Fluted-tipped, self-tapping screws are primarily intended for use in cortical bone.

Sheet-metal self-tapping screws temporarily attach sheet metal in place for riveting. They are used for the permanent assembly of non-structural assemblies where screws need to be inserted in blind applications.

Self-tapping screws are often used to attach removable parts, like nameplates, to castings.

Advantages of Self-Tapping Screws

The simplicity of the self-tapping screw is its vital advantage since it eliminates the need for pre-tapping. Moreover, the number of steps needed for the operation is reduced, which cuts down the operative time. Furthermore, the screws guarantee a tight fit of the screw thread to the material as they create their own thread.

Disadvantages of Self-Tapping Screws

A drawback of self-tapping screws is that they are difficult to tighten. They require increased torque for insertion, making them difficult to tighten. According to the study of Ansell and Scales, using three flutes extended over three threads required the least torque for insertion. However, the pullout strength of the screw's fluted section is weakened since these threads have 17% to 30% less surface area than threads farther up the screw.

A poorly designed tip may face considerable resistance, and the torque required for screw insertion may sometimes exceed the screw's tolerance, causing it to break.

It is crucial to consider the risk of fracture displacement when using self-tapping screws for interfragmentary lag screw fixation in bone surgery. The screws may need extra axial load and torque during insertion, which can cause fracture displacement.

It is essential to use the correct size and shape of the pilot hole to ensure proper thread formation and holding power.

Self-tapping screws are prone to stripping or cracking the boss.

The lack of a chamfered boss in self-tapping screws makes it difficult to be locked.

Self-tapping screws are not meant to be disassembled and reassembled repeatedly, and they may not meet the required standards after being disassembled and reassembled at least 10 times.

🔗Difference Between Self-Tapping Screws and Self-Drilling Screws

Classification of Self-Tapping Screws

Self-tapping screws can be divided into two types: thread-forming and thread-cutting screws.

Thread-forming screws displace material during insertion but not removing it. In contrast, thread-cutting screws have sharp cutting edges that remove the material during insertion. Thread-cutting screws may also have flutes machined into their threads to provide additional cutting edges.

Thread-forming screws

Thread-forming screws create threads by deforming and displacing the material rather than cutting it, which flows around the screw head. Because no material is removed, these screws can create a tight fit with zero clearance and produce significant internal stresses. These screws are affordable and resistant to vibration. They are a good choice for structural foam parts. However, they should be used cautiously in non-foam materials because they may create highly stressed regions. Thread-forming screws allow multiple assemblies and disassemblies.

Thread-cutting screws

Thread-cutting screws feature a sharp cutting edge that removes material chips during insertion. The depth of the preformed hole should be slightly deeper than the screw to accommodate the chips. These screws experience low internal stresses due to the removal of material during installation. They have minimal susceptibility to stress relaxation with temperature changes and time has minimum effect on screw performance.

Thread-cutting screws are unsuitable for repeated assembly as repeated disassembly and reassembly may result in stripped threads. If necessary, the screw should be carefully inserted by hand or replaced it with a machine screw. Thread-cutting screws are suitable for use in solid-wall parts but not recommended for structural foam.

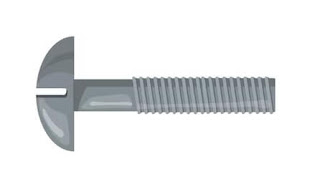

Non-Self-Tapping Screws

Non-self-tapping screws require a pre-drilled pilot hole and threads cut with a tap in the material being screwed into. Non-self-tapping screws lack flutes and have a blunt point. The amount of torque needed to surpass friction is minimal, allowing for a greater portion of applied torque to be transformed into effective tensile force in the screw.

Advantages of Non-Self-Tapping Screws

One of the key benefits of non-self-tapping screws is that they require less axial load and torque during tapping and screw insertion compared to self-tapping screws. This makes them ideal for interfragmentary compression and reduces the risk of fracture displacement. Also, these screws can be replaced without fear of accidental damage since they cannot cut their own channel.

🔗Difference Between Self-Tapping Screws and Non-Self-Tapping Screws