Types Of Centrifugal Pump

🔗Rotodynamic pump and Positive displacement pump

🔗Comparison between centrifugal pump and Positive displacement pump

🔗Centrifugal pump - Applications advantages and disadvantages

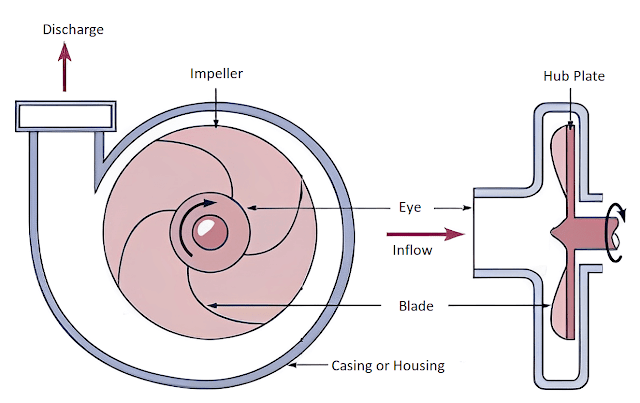

Centrifugal pump, also known as rotodynamic, is the type of pump in which energy transfer occurs when the flow is radial or axial. Centrifugal pump generate pressure by first accelerating and then the decelerating the movement of fluid in the pump. Based on the characteristic feature, the centrifugal pumps are classified into

1. Types of casing

a. Volute pumps

b. Turbine pump or diffuser pump

c. Vortex pump

🔗Types of casing used in centrifugal pump

🔗Difference Between Volute Pump and Turbine Pump or Diffuser Pump

2. Relative direction of fluid flow through the impeller

a) Radial flow pump: Energy transfer occurs mainly when the flow is in radial path. This is the most common type of centrifugal pump.

b) Axial flow pump: Energy transfer occurs mainly when flow is in the axial direction. Designed to give large volume at comparatively low head. Suited for irrigation purposes.

c) Mixed flow pump: Energy transfer occurs in the direction of flow comprising both radial and axial components.

🔗Main components and working principle of a centrifugal pump

3. Working head

a) Low lift centrifugal pump: build up to 15m head

b) Medium lift centrifugal pump: Head up to 40m

c) High lift centrifugal pump: used where the head above 40m required

4. Liquid handled

a) Closed impeller pump

b) Semi-open impeller pump (non clog pump)

c) Open impeller pump

🔗Different types of impellers used in a centrifugal pump

5. Number of the entrance to the impeller

a) Single suction or single entry pump: Fluid admitted to one side of the impeller

b) Double-suction or double entry pump: fluid admitted to both sides of the impeller, the axial thrust is neutralized. It is used where a large amount of fluid is to be pumped.

6. Number of impellers per shaft

a) Single-stage centrifugal pump: its casing has one impeller. For low lift pumps.

b) Multi-stage centrifugal pump: more than one impeller in the casing. Pressure built in steps. For high lift pump.

🔗Types of Sealless pump, applicaton and advantages