Different Types Of Impellers In A Centrifugal Pump - Their Application and Advantages

🔗Main Parts of a Centrifugal Pump

There are three types of impellers used in a centrifugal pump.

Shrouded or closed impeller

In this impeller type, metal cover plates or shrouds are provided on both sides of the impeller vanes, enhancing its strength. This reduces the load on the shaft, increasing bearing life. However, its complicated design makes it more difficult to manufacture and more expensive than open impellers. These impellers typically have plain vanes with a single curvature that are curved backwards. Wider impellers have double-curved vanes with twisted suction ends. These are known as mixed flow vanes or Francis type vanes.

Closed impeller has high efficiency and offers better liquid guidance. It is used in large pumps where the liquid that needs to be pumped is pure and relatively debris-free. These impellers can't effectively perform with solids and become difficult to clean if clogged.

Semi-open impeller

A semi-open impeller has vanes that do not have a crown plate but only a base plate. This impeller can be used even if the liquids contain small amounts of debris at the cost of reduced efficiency. These impellers have fewer vanes, but they are longer in order to avoid clogging.

🔗How to choose the right centrifugal pump impeller material for different applications?

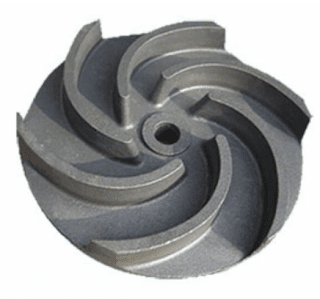

Open impeller

The figure shows an open impeller without any protective shroud. The vanes have no crown plate and no base plate. i.e. the vanes are open on both sides. So they are structurally weak. Because its internal parts are visible, it is easy to inspect for damages to the open impeller. Sand locking is less common than with closed type. Additionally, it is simpler to change their flow characteristics.

These impellers are used in very rough applications and are therefore made of material with excellent wear and impact resistance. Such impellers are used for pumping liquids containing suspended solids. (e.g. water containing sand, pebbles, sewage water, and paper pulp). But they require a higher NPSH (Net positive suction head) to operate without cavitation, damage and loss of efficiency.

(1).png)