Various Types of Casing Used in Centrifugal Pump - Benefits and Limitations

🔗Main parts of a centrifugal pump

Volute casing

The volute casing is the most common type of casing in centrifugal pumps. Derives its name from its spiral shape. The cross-sectional area or flow area gradually increases uniformly from the tongue (impeller outlet) to the delivery pipe. The shape of the volute's cross-section can be circular, trapezoidal or rectangular, depending on the design. As the area of passage increases gradually, the velocity of fluid decreases and pressure rises in the volute casing. In other words, the kinetic energy is converted into pressure energy.

The main drawback of this casing is eddies formation, which results in energy loss. It is important to note that these casings only convert a small amount of velocity head into pressure head. A lot of the velocity head is lost in eddies. Therefore, these pumps generally produce low heads.

There are two types of volute casings, Single volute casing and Double volute casing.

Single-volute casing designs are based on constant velocity. The main advantage of a single volute casing is that it can be easily cast and manufactured at a low cost.

Two volutes with an arc of 180° make up the double volute casing. The second volute begins 180° after the starting point of the main volute. This type of volute could be the right choice for a pump with a flow rate higher than 125 m3/h.

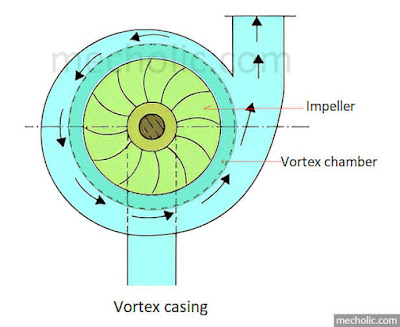

Vortex casing or Whirlpool casing

In vortex casing, circular chamber known as vortex or whirlpool chamber is provided between the impeller and the volute chamber. The circular chamber acts as diffuser. The liquid leaves the impeller and enters the vortex chamber with a vortex motion acting as a free vortex. The Pressure head increases as kinetic energy decreases radially outward from the center. After leaving the vortex, fluid enters the volute, where further pressure head is achieved. Elimination of eddies can also be achieved by employing the circular chamber. The loss of energy due to eddy formation has been considerably reduced. As a result, vortex casing is more efficient than the simple volute casing.

🔗Difference Between Volute Pump and Turbine Pump or Diffuser Pump

🔗Types of Sealless pump, applicaton and advantages

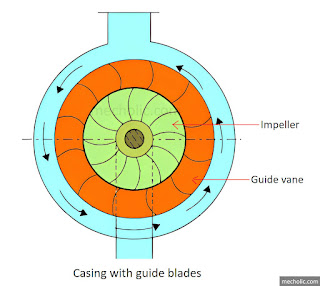

Casing with guide blades (or diffuser type casing)

In this type of casing, series of guides vanes known as diffuser are symmetrically placed at the outlet of the impeller. The diffuser ring should have more vanes than the impeller but not allowed to be excessively high. Usually, a diffuser ring has one more vane than an impeller. The passage between the guide vanes gradually widens so as the spaces between the vanes that act as a volute. While liquid passes through the guide vane, the kinetic energy decreases and pressure energy increases. It offers a significant improvement in efficiency by up to 75%.

The diffuser pumps are used to develop high head by multi-stage operation; it is seldom applied to a single-stage volute pump. For single stage, volute and vortex casing are preferred.

🔗Major functions of casing in centrifugal pump

🔗Different types of impellers used in a centrifugal pump

A poorly designed diffuser can reduce the hydraulic characteristics of a pump. The fast-moving liquid from the impeller and diffuser can meet without shock only when operating at rated capacity. At other flow rates, the multiple vanes cause shock and turbulence, making it difficult for this pump to operate at its full potential. So, they are less reliable when operating under a wide range of conditions. Because construction is complicated, these pumps are more expensive than volute pumps.