Flat Belt Drive - Types, Advantage and Disadvantage

Types of flat belt drive

Flat belts are the simple system for power transmission. It can deliver high power to moderate distance (up to 15m).Flat belt drives further classified into

Open belt drive

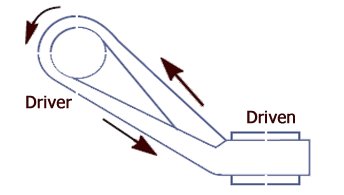

In an open belt drive, shafts are arranged in parallel and rotate in the same direction. The driver pulls the belt from the lower side and delivers it upper side of the pulley so that lower side is always tight and slack is on the top side.Cross belt drive

Cross belt, also known as the twisted belt, is twisted as shown fig. In a cross belt drive, the shafts are arranged in parallel, and twisted arrangement makes pulleys rotating in the opposite direction. The speed is limited to 15m/s to avoid excessive wear. Both sides of the belt get contact with pulleys, so this arrangement not advisable for V-Belt and Timing Belt.🔗Difference between Open Belt Drive and Cross Belt Drive

🔗Difference between Flat Belt Drive and V-Belt Drive

Quarter turn belt

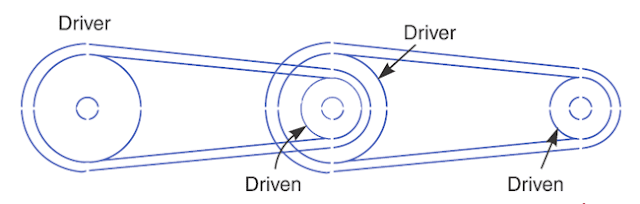

Also known as the right angle belt drive. In this type, shafts are arranged at right angles.Compound belt drive

Compound belts are similar to open belt drive. They used to power transfer through one or more intermediate pulleys.Also known as the jockey pulley drive. Idler pulleys are pressed against the belt and guide them. They change direction and increase the angle of contact. It can provide a high-velocity ratio. Idler pulleys can also reduce the vibration in the belt.

Stepped or cone pulley drive

They are used to get different velocity ratio during the power transfer. The driver shaft rotates at constant speed, driven shaft can run at a different speed as the belt shifting from one cone pulley to another.🔗Advantages and Disadvantages of Pulley used in power transmission (Pulley Drive)

Fast and loose pulley drive

It is used to stop the machine while driver continues to run; this can accomplish by shifting the belt to a loose pulley, which is freely run over the shaft.

Advantage of the flat belt drive

- The flat belts are very simple in design and cheaper.

- Smooth running and quiet running.

- Flat belts can be used for long distances, even up to 15 m.

- Precise alignments of shafts and pulleys are not as critical with flat belts.

- The periodic adjustment of the belt tension and belt replacement, when it is worn out, is easier in the case of flat belts.

- Flat belts are and very flexible and, therefore, they have the ability to bend and twist on pulleys and follow very tortuous paths.

- Flexible and longer belts can absorb shock and torsional vibration. Therefore, they are quieter and have better protection of machine against knocks or overloading.

- Fast and loose clutch action and variable output speed by cone pulley drive are possible with flat belt drives.

- They are durable.

Disadvantage of the flat belt drive

- High chance of slip off.

- Compared to v-belts, flat belts require significantly greater of pretension to transmit a certain torque without slip.

- Flat belts are not advisable for high outputs at high speeds. The flat belt cannot transmit high power as timing belt does.

- They are bulky, for a given transmission, flat belt drive requires a wide pulley.

Read:

V-Belt Drive - Advantages and disadvantages

The materials used for belt drive

Causes of belt failure and Power loss

Why slack side is on upper side of flat belt drive