Working of Diffusion Pump

What Is a Diffusion Pump?

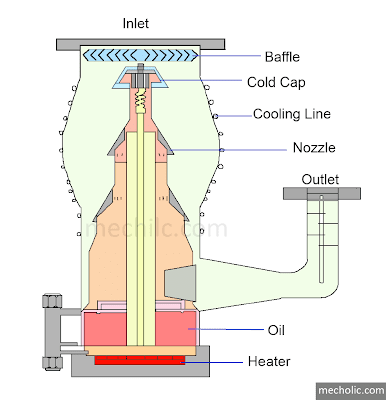

A diffusion pump is a high-vacuum pump that operates without moving parts using a high-velocity vapour jet to transfer momentum to gas molecules and expel them from a vacuum chamber. This momentum transfer mechanism enables vacuum levels as high as 10-7 to 10-9 torr.

A diffusion pump is categorised as a "momentum transfer pump" and falls under the general category of vacuum pumps. It works by directing a stream of heated vapour, typically a type of oil, downwards through nozzles at very high, supersonic speeds. This vapour jet literally "knocks out" gas molecules from the vacuum space by hitting them at high enough velocities.

A reservoir of viscous fluid at the bottom of a diffusion pump acts as the working substance. This fluid is heated in the 'boiler' section to turn it into a vapour. This vapour rushes up centrally and is accelerated through a set of nozzles that give it very high speeds. The fast-moving vapour molecules collide with stationary gas molecules and impart momentum to them. This transfers kinetic energy to the gas molecules, providing the pumping force to expel them through the exhaust.

By providing substantial momentum transfer without being limited by mechanical motion, diffusion pumps can create high vacuums efficiently. However, they need a backing pump to handle the exhaust. The diffusion pump itself only "kicks out" molecules using momentum transfer through directed vapour flow.

The key things that characterise a diffusion pump are:

- No moving parts

- Momentum transfer by high-speed vapour jet

- Requires separate backing pump

- Enables high and ultra-high vacuums

Diffusion Pump Components

Essential parts inside a diffusion pump include:

Working Fluid: Typically, a type of high molecular weight oil

Boiler Section: Has heaters and contains fluid reservoir

Vapor Jet Assembly: Central chimney and nozzles

Pump Body: Main cylindrical casing with cooling jacket

Backing Port: Exit for expelled gas molecules

These components generate the high-speed vapor jet and provide continuous fluid recycling while removing gas molecules.

Diffusion Pump Systems and Accessories

While the diffusion pump generates a high vacuum, supporting subsystems and accessories enable specialised functionality and optimal operations. Accessories for diffusion pumps encompass baffles, fluids, cold caps, heaters, centering rings, and thermal switches.

Baffles

Baffles are devices used to control gas or vapour flow direction within a vacuum system. User-configurable concentric chevron baffles mounted atop diffusion pump nozzles provide conductance control to balance pumping speeds versus the risk of oil backflow into the chamber and outgassing.

Cold Caps

Cold Caps effectively halt back streaming like an optically dense baffle while retaining 80% of the pump's speed.

Cryogenic Cooling

Large thermal shrouds filled with liquid nitrogen provide cryogenic condensation surfaces for any vapour molecules reaching the top, equivalent to cold traps. This maximises the containment of oil within the diffusion pump body.

Thermal protection switches

Thermal switches in diffusion pumps serve to prevent system overheating conditions.

Centering Rings

Centering Rings for Diffusion Pumps play a crucial role in ensuring secure seals within the system.

Vacuum Gauges

Vacuum gauges are instruments used to measure the vacuum level within a system. Different types of vacuum gauges exist, such as thermocouple gauges, ionisation gauges, and capacitance manometers, each suited for specific pressure ranges and applications.

How Diffusion Pumps Work

Diffusion pumps enable high vacuums to be reached by imparting momentum from a high-velocity vapour jet to the gas molecules that need to be removed from a vacuum chamber. This jet literally "knocks out" the stationary molecules through momentum transfer.

A diffusion pump has no moving parts. It relies on heating a working fluid to generate a vapour jet within an enclosed casing. This jet flows in a directed manner from top to bottom and is forced to have high speeds through a set of nozzles. The fast vapour molecules collide with stationary gas molecules, imparting kinetic energy that provides the pumping force.

Function Diagram

A simple diffusion pump contains these key components:

Boiler/Heater: Heats oil reservoir to vaporisation point

Nozzles: Accelerate vapour molecules to supersonic speeds

Pump Body: Cooled walls cause vapour jet to condense

Outlet: Connects to a separate backing mechanical pump

The boiler generates high-velocity vapour from the working fluid while the nozzles focus this vapour into a jet. The cooled body causes condensation of the spent vapour, which gets recycled back to the boiler.

Start up and Warmup

Before initiation, the diffusion pump body needs to reach the fluid's boiling point to generate vapour. This is done by providing power to electrical heaters in the boiler reservoir. Warmup from cold to operating temperatures typically takes 15-30 minutes. Rushing this process risks damaging the pump.

Vapor Jet Momentum Transfer

The vapour jet forms the core mechanism for momentum transfer. As vapour accelerates through the nozzles and exits at supersonic speeds, it collides with stationary gas molecules from the chamber. By conservation of momentum, these molecules attain high velocity and kinetic energy, enough to exit from the pump completely. This imparting of momentum provides the pumping action.

The high-speed vertical jet makes it unlikely for molecules to diffuse backwards. The continuous operation means gas molecules wandering into the jet are eventually expelled. This mechanism generates a high vacuum in the connected chamber.

Backing Pumps

A separate backing pump, typically a mechanical rotary pump, handles taking away the exhausted gas load. It cannot allow pressure to rise enough to limit the diffusion pump outlet flow. So, an adequately sized backing pump is essential for stable functioning.

Cooling Diffusion Pumps

Diffusion pumps require extensive cooling to condense the high-velocity oil vapour jet and liquidise the spent fluid after it transfers momentum to gas molecules. Maintaining operating temperatures against internal heat generation and dissipating this heat outside is pivotal to consistent diffusion pump functionality.

🔗Maintenance of diffusion pump

Water cooling is the most common method. Water is circulated through cooling coils and jackets around key areas like the pump body, cold cap, baffles etc. Air cooling can work for smaller pumps but is less effective. Oil diffusion pumps achieve optimal functionality with wall temperatures as high as 30°C, in contrast to mercury diffusion pumps that require cooling to 15°C for efficient operation.

Ensuring adequate coolant flow is critical to prevent uncontrolled heating. Flow sensors connected to automated interlocks will trigger an emergency shutdown if the coolant pump fails or blockages occur. This protects the diffusion pump from internal damage.

Proper insulation around the pump exterior also optimises energy efficiency. Along with heating and cooling systems, instruments like thermocouples continuously monitor temperature zones.