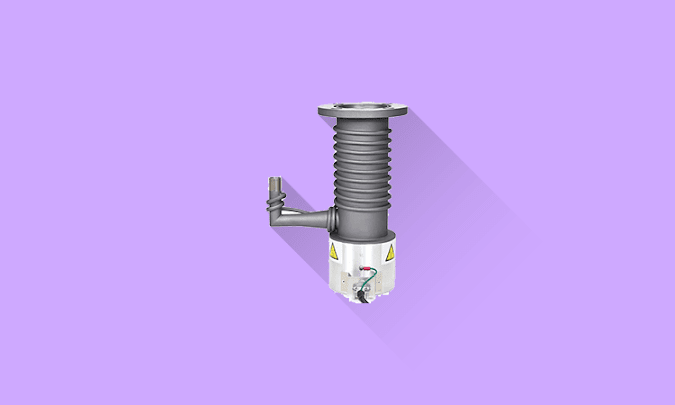

Diffusion Pump Applications, Advantages and Disadvantages

🔗What is diffusion pump? How it works?

Diffusion Pump Applications

Diffusion pumps are well suited for generating stable high vacuums across various industrial and research applications. They excel when very high gas volumes need to be handled without contamination. From large industrial coaters to small university labs, the versatility of oil diffusion pumps makes them a pragmatic choice for quickly generating stable high vacuums.

High Vacuum Environments

In any setting requiring clean vacuum environments below 10-5 mbar, such as vacuum coating processes, diffusion pumps can efficiently generate the needed pressures. Silicone oils tolerate moisture and oxygen that would contaminate other pumps.

Industrial Use Cases

Coating - Large area vacuum coating systems rely on oil diffusion pumps to reach needed vacuum pressures for quality thin film deposition.

Electron Beam Welding - The working chamber where parts are directly exposed to electron beams requires 10-5 to 10-6 mbar pressures. Within this chamber, the treated workpieces produce dust and hydrocarbons. To handle these conditions, the oil diffusion pump is employed as the standard pump, chosen for its lower sensitivity to dust and hydrocarbons when compared to turbomolecular or cryopumps.

Vacuum Furnaces - Vacuum heat treatment needs at least 10-3 mbar and benefits from diffusion pumps that can handle hot inert gases well.

Research Applications

Many physics experiments needing clean, high vacuum environments depend on diffusion pumps. The lack of vibrations and oil contamination makes them suitable where other pumps may interfere. Their simplicity of operation also allows focusing on the science itself.

Other application includes.

- Purification degassing

- Vacuum brazing and soldering

- Vacuum distillation and sterilisation

- Space simulation chamber

Advantages and Disadvantages of Diffusion Pumps

Diffusion pumps have unique strengths but also limitations compared to other high vacuum pump technologies. Understanding these pros and cons allows appropriate selection.

Advantages

- Simple, robust construction

- Low initial cost

- Easy to service.

- No moving parts, high durability

- Low noise and vibrations

- Excellent resilience against magnetic fields and radiation

- They can be constructed without significant challenges to accommodate exceptionally high flow rates.

- Can achieve ultra-high vacuums.

Disadvantages

- Prone to back streaming

- Oil contamination risks.

- If oil is exposed to air, it has the potential to ignite fires or cause explosions, as certain utilised working fluids possess combustible properties.

- Needs a separate backing pump.

- Has thermal hazards

- Vertically constrained

- Regularly, the oil needs replacement.