What Is a Magnetic Drive Pump? How Does This Work? Advantages And Limitations

Magnetic drive pump construction and working

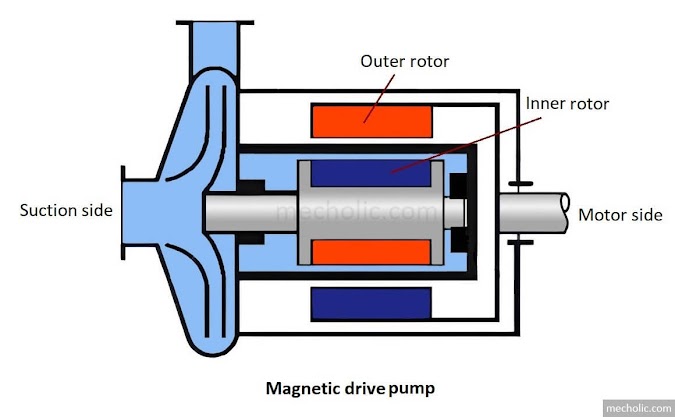

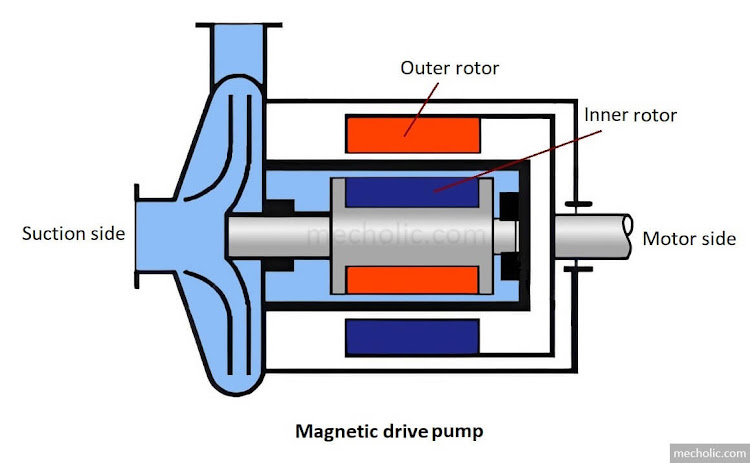

Magnetic drive pumps were designed to pump toxic and hazardous fluids without using mechanical seals. This is achieved by retaining the fluid inside a containment shell. The principle behind magnetic drive technology is that there is no shaft penetration of the pressurized part of the pump casing. Instead, the pump rotor is driven by magnetic flux. In magnetic drive pumps, the rotor comprises an impeller, shaft, and driven magnets (inner magnet), all operating inside the pumped liquid. The driven magnets take their drive from the rotating drive magnets (outer magnet), which are assembled on a different shaft that is coupled to the prime mover. This type of pump utilizes a conventional electric motor as the prime mover that drives a set of drive magnets that drive other magnets fixed to the pump shaft.

Outer cylinder includes a cylindrical magnetic ring. The outer magnet is supported by the pump bearings and rotates with the motor. The second magnetic cylinder is located inside the pressurized part of the pump casing and secured to the pump rotor. The outer and inner magnetic cylinders are separated from each other by a containment can or shell. A non-magnetic housing of corrosion-resistant alloy, such as Hastelloy or plastic in lighter-duty versions isolates the pumped liquid from the environment and separates the rotating magnet sets.

The magnetic cylinder attached to the rotor is able to rotate because of a flux of magnetic force between the inner and outer magnets. This makes the pump impeller rotates, which pumps liquid without any shaft penetration from the pressurized pump casing.

There are two kinds of magnet drives: eddy current electromagnets, which can experience some slip inside the pump and decouple, and rare earth permanent magnets, which do not have a slip and are not subject to decoupling.

Read: Difference between magnetic drive pump and canned motor pump

Advantages and disadvantages of magnetic drive pump

Advantages of magnetic drive pump

- No mechanical seal.

- It use standard motor.

- Require very little maintenance.

- Leak-proof pumping has been achieved.

- No product loss.

- No exposure to corrosive, flammable, or explosive liquid and gaseous to workers or the environment.

- Heat tolerance is better than the canned motor pump.

- The containment shell is larger than that of canned motor pumps and is considered more reliable.

Limitations and disadvantages of magnetic drive pump

- Higher initial cost and repair cost. Since maintenance is low, a quick payback can be attained.

- Not good at handling abrasives. Even for a small percentage of solids, magnetic drive pumps are unsuitable because they only work with liquids free of solids.

- A magnetic drive pump tends to heat the pumped liquid. It is vital, especially when the liquid being pumped is heat-sensitive. Heat generation causes low efficiencies.

- Not as efficient as conventional pumps. Magnetic drive pump must be operated very close to the BEP (best efficiency point) on the curve.

- It cannot run dry. The working fluid lubricates the impeller bearings in magnetic drive pumps. However, this may not be a good idea because it may not be an appropriate lubricant for these parts. When the pump runs dry, the lubricant runs out, and the bearings get overheated.

- Magnets are sensitive to temperature and will demagnetize if exposed to temperatures above their upper limit.

- The magnets may get decoupled. Then requires stopping and restarting the pump.

- It cannot resist extended cavitation.

- It may require larger motors.

- Magnetic drive pumps have very little tolerance for pipe strain.