Canned Motor Pump Working, Application, Advantages And Disadvantages

What is a canned motor pump?

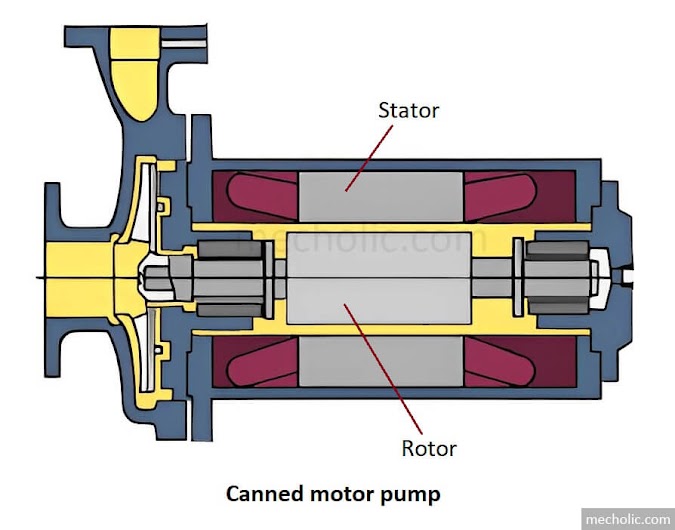

Canned pumps are sealless pumps. One of the notable features of the canned motor pump is the integral construction of pump-motor and the absence of a shaft seal. As shown in the above figure, it is a close-coupled unit in which the motor housing cavity and pump casing are interconnected. The motor, pump shaft and bearings operate wet inside the pumped liquid. Hence the hazardous or toxic liquid is confined within this containment shell.

The pump section is nearly identical to that of a conventional centrifugal pump and has the same pumping characteristics. These pumps incorporate an electric motor hermetically sealed inside the pump casing and a containment shell. In this type of pump, torque is transmitted magnetically. The rotating flux generated by the stator passes through shell and drives the rotor and the impeller. Motor bearings run in the process liquid, which acts as a lubricant. The liquid that passes through the pump's discharge port is fed to the rotor chamber through the circulation tube or hollow shaft, which cools the motor and lubricates its bearings. The liquid then flows back into the pump chamber, which allows it to be pumped again.

Applications of canned motor pumps

These pumps have been developed to help businesses comply with environmental and safety regulations regarding fugitive emissions. Examples include handling organic solvents, heat transfer liquids, light oils and many clean toxic/hazardous liquids for plants where leakages are environmental and economic problems. They are used for pumping clean liquid because bearings are susceptible to damage from solid particles in the fluid (abrasion). Because these pumps do not have a possibility of leaking, they are ideal for handling liquids that are harmful to humans, explosive or flammable liquids, expensive liquids, corrosive liquids, etc.

Read: Difference between magnetic drive pump and canned motor pump

Advantages and disadvantages of canned motor pumps

Advantages

- Requires no mechanical seal.

- Fewer bearings.

- Low failure rate.

- Considered as leak-proof. No product loss.

- Double containment. Safe for pumping hazardous fluids.

- No lubrication is needed. So, the transported fluid is not contaminated due to the lubricant.

- The design is compact, lightweight, and easy to install and maintain.

- No alignment is required.

- Able to withstand a wide range of pressures and temperatures.

- No product exposure to workers or the environment.

- Because the pump has no outside air intake, it is suitable for use in a vacuum or for handling liquids that are sensitive to the outside air.

- Quiet running because there is no fan to cool the motor.

Disadvantages

- Higher initial cost and repair cost.

- Fine abrasives in process liquid will damage bearings.

- The pump must be operated very close to the BEP (best efficiency point) on the curve.

- It cannot run dry or under cavitation.

- The can may fracture.

- Less efficient than conventional pumps.

- It cant handle high temperature as magnetic drive pump. Higher temperature pumping required external cooling of stater to prevent winding failure.

- It may consume more energy (BHP) than conventional pumps.

- Cannot see the direction of rotation of the pump. Special instrumentation is required to determine the rotation.