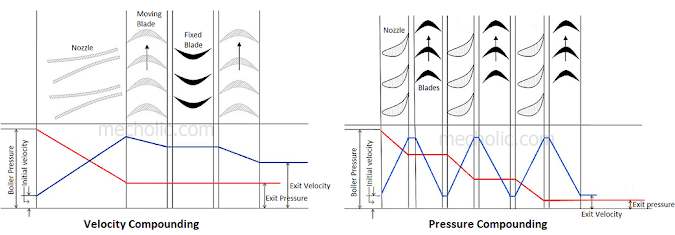

Difference between Velocity Compounding Turbine and Pressure Compounding Turbine

🔗What is meant by compounding of turbine? What are the advantages of compounding?

🔗Velocity compounding - working with pressure velocity curve

🔗Pressure compounding working, advantages and disadvantages

🔗Velocity compounding - working with pressure velocity curve

🔗Pressure compounding working, advantages and disadvantages

Comparison between velocity compounding and pressure compounding

Velocity

Compounding turbine

|

Pressure

compounding turbine

|

Velocity/ Kinetic energy of steam is

converted to useful work in more than one stage.

|

Pressure energy of steam at turbine

input gradually extracted in multiple steps

|

Pressure of steam remains constant in every fixed blade and moving blades

except in the first nozzle.

|

Pressure of steam decrease in every nozzle (fixed blades)

|

Velocity of steam increase in every nozzle (fixed blade). Steam velocity decrease

in every moving blade

|

|

High velocity of steam inside the turbine.

|

Velocity of steam is low when compared to velocity compound turbine.

|

High frictional losses

|

Low frictional losses

|

Fewer number stages, and hence the

turbine length is short, require less space

|

Large number of stages and it is bulky, require more space.

|

It gives maximum output at the first

stage, work produced in the low-pressure stages is much less.

|

Same amount of work produced in each

stage.

|

Less efficient

|

More efficient

|

High steam consumption

|

Less steam consumption when compared

to velocity compounding.

|

Ratio of blade velocity to steam velocity is not constant (not optimum for

all blades)

|

Ratio of blade velocity to steam velocity is constant.

|

Steam pressure inside the turbine is

literally equal to the atmospheric pressure so there will be no problem of

steam leakage.

|

High pressure of steam inside the turbine. The chance of steam leakage

will be more when compared to velocity compounded turbine.

|

The casing of the turbine need not be airtight.

|

Turbine casing should be airtight.

|