Multiple Venturi Carburetor Construction and Working, Advantages of Multiple Venturi Carburetors

🔗Construction and working principle of simple carburetor

🔗Essential parts of modern carburetor and their functions

How multiple venturi carburetor works?

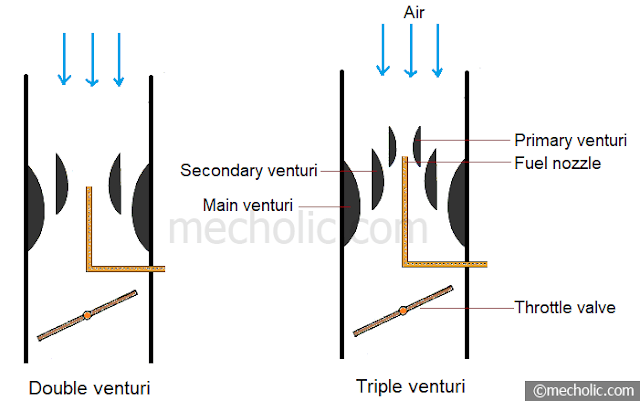

When one or more secondary venturi concentrically enclosed inside the main venturi of carburetor, then it is called multiple venturi carburetor. The secondary venturies are known as boost venturi. The boost venturi located at the upstream of the main venturi. The boost venturi positioned in such a way that the discharge end is located at the throat of main venturi and the pressure at the exit of boost venturi is equal to the throat pressure of main venturi. In this arrangement, only a fraction of air flow thought the boost venturi. The fuel nozzle is located at the throat of boost venturi.Double venturi has two venturies present in the induction tract. In some arrangement, three venturi is used (triple venturi). In triple venturi, the venturies are named main, primary, and secondary venturi. These arranged in such a way that outlet primary venturi is placed in throat of secondary venturi, the outlet of secondary venturi is at throat of main venturi.

In multiple venturi system, the fuel nozzle is kept opposite direction of air flow through the primary venturi. At the throat of primary venture, the fuel gets atomized by air stream. The atomized fuel is then centrally located in the air through the primary venturi. During the atomization, the blanket of air surrounding the primary venturi move to the secondary venturi unit keeps the fuel centrally located in the air stream. This type of air flow prevents the fuel coming into contact with the carburetor walls for certain distance, thereby reducing the chance of condensation of fuel.

Advantages of multiple venturi carburetor system

Results and benefits of multiple venturi arrangements are listed below.- Better atomization, and control of fuel due to the high depression created at the region of fuel nozzle (boost venturi throat). The velocity will be high as 200m/s

- Excellent air-fuel mixing is achieved without any significant reduction in volumetric efficiency. The reduction in volumetric efficiency is negligible because only a very small portion of incoming air is subjected to high pressure drop.

- Reduce the condensation of fuel: An annular blanket of air is formed and surrounds the primary venturi, which will keep the fuel droplet away from the walls of induction tract.

- The excellent low-speed full throttle operation.

- Nearly constant air-fuel ratio is maintained by high speed system. To increase speed of engine, the throttle is opened sufficiently. Wider opening of throttle valve results in faster flow air flow through the primary venturi. This high speed air flow produces high pressure drop (vacuum) at the region of fuel jet. An addition fuel is then discharged due to this increased vacuum.