Choosing Locating Surfaces; Based On the Surface Shape of Component

Types of locating surface/ the basic principle of location

The different locating method with respect to the surface of workpiece. The designer should carefully study the workpiece before deciding the best suited locating surface. The location commonly from the following surfaces- Locating from plane surface

- Locating from circular surfaces

- Locating from irregular surfaces

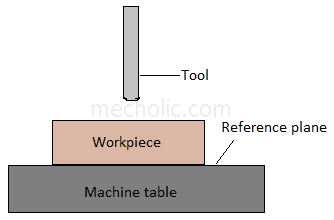

Locating from plane surface

In this type, the flat machine table act as the basic reference surface. The machine table supports the workpiece, act as a stop and locating surface. If the workpiece does not have at least one flat side, the flat table cannot use as locating surface.

🔗Different types of Locating methods and devices

🔗3-2-1 Principle of Location (Six Point Principle)

Locating from circular surface

In this type machine table act as the reference plane for location. V block, conical locator are commonly used for locating circular workpiece.In V locator, the “V” should be directed in such a way that the variation of the dimension of workpiece will not affect the location. In Fig (a) the variation of diameter of workpiece will not produce an off-center. In fig (b) the difference in diameter produces an off-center, which is not preferred in the drilling operation.

Locating from irregular surfaces

The workpiece is neither flat nor circular. If the diameter of workpiece varies from point to point or the surface is rough, then the surface is called irregular surface. It is advisable to use equalizers or adjustable rest pins to compensate the irregularity of surface.Fig shows two v-block locators, one is fixed, and other is movable (sliding v-block). ‘V’ with an angle 90° is the most commonly used v-block in jig and fixture.