Abrasive Jet Machining (AJM) Working Principle and Process Parameters

Principle of AJM

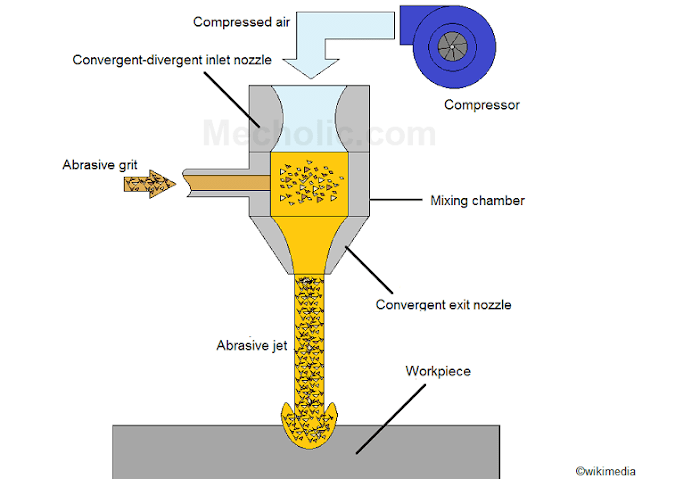

Abrasive jet machining process uses the mix of fine-grained abrasive material with any suitable gas or air for metal cutting. High pressured particle-gas mixture is directed in a controlled manner by using specially designed nozzles and made them impinge onto workpieces. The fundamental principle of AJM involves the stream of abrasive particle at the high velocity. ( Read: How high-pressure fluid is get converted into high-velocity fluid - Bernoulli’s principle). The metal removal occurs at the material surface due to the erosion effect of the high-velocity abrasive particle jet. The particle removes material by both micro cutting and brittle fracture of work material. The mechanisms of material removal in AJM are ductile fracture and brittle fracture.Process parameters in AJM

The abrasive particles used in AJM are - Aluminium oxide (Al2O3), Silicon carbide (SiC), glass bead of 10-50µ for machining, Sodium bicarbonate for polishing work.

The gasses used in AJM are CO2, N2 or dry air at 2 to 10bar.

The velocity of the abrasive jet is about 300 m/s.

The nozzle material is Tungsten carbide (WC) or synthetic sapphire with a diameter of 0.2 - 1mm. Expected life of the nozzle is 300 hrs for sapphire and 30 hrs for WC

The normal NTD (standoff distance) varies from 0.5 -15 mm

🔗 Abrasive Jet Machine setup and construction details

🔗 Applications, advantages, and disadvantages of AJM

🔗 Different abrasive particle used in ajm and their specific applications

How AJM differ from sand blasting?

- AJM is used for continues material removal or cutting while sandblasting used for smoothing rough surfaces.

- In ajm finer abrasive particle is preferred (grain size less than 50µ).

- AJM has more efficient control over the cutting parameter and delivery system.

- AJM give good surface finish than sand blasting.