What Are the Various Factors Influencing Flame Propagation?

Abnormality in SI engine like detonation is depends on the rate of pressure rise in the combustion chamber. Since the rate of pressure rise directly related to the rate of flame propagation, it is very important to study about the factors affecting flame propagation. Important factors that influence the flame propagation is listed below.

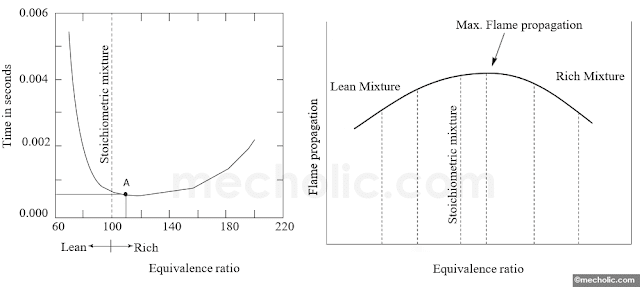

Fuel-Air ratio

Stoichiometry of charge has a significant influence on the rate of combustion and heat generated. Following figure shows the relation of fuel-air mixture strength on time taken for the complete combustion of fuel. The highest rate of combustion and hence the highest flame speed is obtained by a somewhat richer mixture. For hydrocarbon fuel, the maximum flame propagation occurs at nearly 10% richer mixture. When mixture made leaner or richer, flame speed decreases.Compression ratio

When the compression ratio increases, the total combustion time decreases. I.e. engine having high compression ratios have high flame propagation speed. High compression ratio results in high pressure and temperature in the combustion chamber, which reduce the initial preparation phase for combustion. When compression ratio increases, the clearance volume decreases, hence the density of charge increases and concentration of residual gases decreases. This increase peak pressure and temperature during the burning. High pressure and temperature also facilitate the second phase of combustion. Even though the high compression ratio favours the flame propagation, it is not recommended to push the compression ratio beyond a certain limit since it causes high temperature and eventually detonation in the engine.Intake temperature and pressure

Flame propagation speed increase with an increase in intake temperature and pressure. Higher intake pressure and temperature help to form better homogeneous fuel-air mixture. It also increases the density of the mixture, which increases flame speed.Turbulence

Flame speed is high in the turbulent mixture than the non-turbulent mixture. Turbulence cause better intermingling of burned and unburned mixture particle at the flame front. This increases the rate of contact, heat transfer rate, and accelerate the chemical reaction, which increases flame speed. However, very excessive turbulence cools the flame ad it may extinguish the flame, which results in roughy and noisy combustion.It is always desirable to have moderate turbulence to accelerate the chemical reaction and increase flame speed. The favourable turbulence of intake charge is generated by suitable design changes of the intake pipe, valve opening, cylinder head, piston crown, etc. The turbulence which consists of many minute swirls appears to be having a high rate of reaction and high flame propagation than the turbulence consists of the fewer number of large swirls.

Engine speed

Increase in Engine speed increases the turbulence of charge inside the combustion chamber. The flame speed is also almost linearly increase with the increase in engine speed. When the engine speed doubled, the flame speed also doubled; in other words, the time taken for the complete combustion is halved. Hence the crank angle for the complete combustion will remain almost constant irrespective of the engine speed.Engine size

Engine size does not have any significant effect on the rate of flame propagation. In large engine, time for complete combustion is more because the flame has to travel more distance to complete the combustion. This increase the crank angle duration for the complete combustion. This is the reason why large engine designed to lower speed working.Engine load/ engine output

When the load on the engine increase, the cycle pressure is also increasing. The power output of the SI engine is controlled by throttling. The density of charge admitted into the cylinder is proportional to the throttle opening. Increase in density results increases in flame speed. When the load decreases the density of charge admitted into the cylinder also decrease. This results in the trouble in flame propagation. So, the SI experience poor performance at low loads. To avoid that necessary enrichment of fuel is required, which cause wastage of fuel and incomplete combustion of fuel. It is one of the main disadvantages of the SI engine working at low loads.Some other factors influencing the flame speed are

- Type of combustion chamber

- Spark timing

- Supercharging

- Residual gas left in the chamber