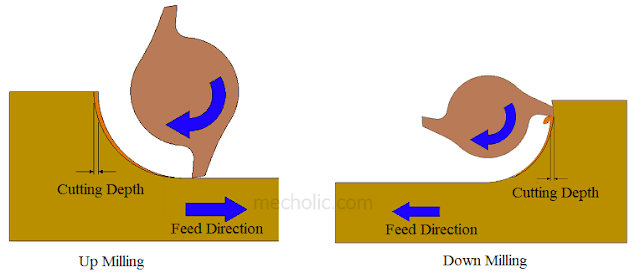

Difference between Conventional Milling and Climb Milling

Read: Elements of Plain Milling Cutter - Nomenclature and Angles

What Is Milling and Milling Cutters?

Here is the quick comparison between conventional milling and climb milling.

Conventional Milling

|

Climb milling

|

Also known as up milling.

|

Also known as down milling.

|

Milling cutter rotates against the direction of feed of workpiece.

|

Milling cutter rotates in the same direction of feed of workpiece.

|

Up milling requires higher force.

|

Down milling requires lesser force comparing to up milling.

|

Chip thickness is zero at the entrance of cutting tooth and maximum at

tooth exit.

|

Chip thickness is maximum at the entrance of cutting tooth and minimum

at tooth exit.

|

Cutter has the tendency to pull away from the workpiece from Workbench.

|

Cutter tends to push the workpiece against Workbench.

|

It needs intrinsic work holding device to hold workpiece against

pulling force of cutter.

|

Cutter pushing the workpiece towards the workbench, so there is no need

of special fixture to hold against the force acting by the cutter.

|

Cutting process leaves chips ahead of the cutter. It is carried upward

by the tool.

|

Cutting process leaves chips behind the cutter. It is carried downward

by the tool.

|

Chip disposal is difficult.

|

Chip disposal is easy when compared to Conventional Milling.

|

No tendency to drag workpiece towards the cutter.

|

It tends to drag workpiece into the cutter.

|

Surface finish is poor when compared to climb milling. Generally used

for the rough cutting operation.

|

Good surface finishing, generally used for finishing operation.

|

Tool life is low compared to that of down milling.

|

It possesses longer tool life.

|