Dall Tube Flow Meters – Application, Advantages, Disadvantages

🔗Differential pressure flow meter working principle (Derivation and Equation)

🔗Differential pressure flow meter - working, applications, advantages and limitations

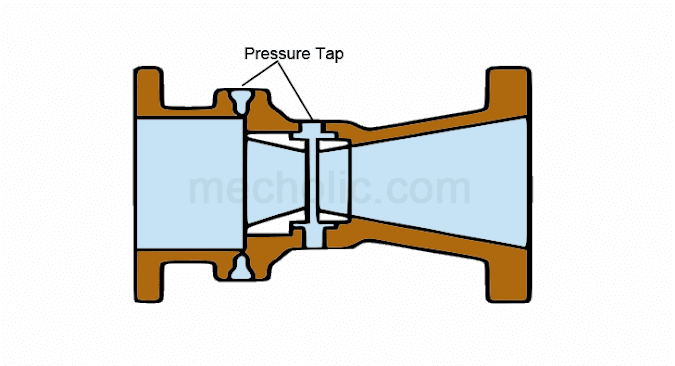

It is another restriction type primary element for flow measurement. It is a shortened/ modified form of a Venturi meter. The differential pressure of Dall tube is midway of the orifice and venturi tube.

It consists of two sections, with relativity large cone angle. The short straight inlet followed by an abrupt decrease in diameter. A narrow annular slit separates the short inlet and divergent outlet. The throat is formed by a circumstantial slit located between the inlet and outlet cones. The higher pressure is measured at circular slit area, and lower pressure is measured at upstream. Typically a lithium coating is provided to avoid corrosion of the device by the fluids.

The differential pressure produced by Dall tube is much higher, nearly doubled to that of Venturi meter having the same upstream and throat diameters with the same net head loss. It causes a very low-pressure loss compared to other differential pressure flow elements. Up to 95% Differential pressure can be recovered.

- Types of Orifice Plates - Advantages and Disadvantages (Concentric, Eccentric, Segmental, Quadrant Edge)

Advantages, disadvantages and limitation of Dall tube

Advantages

- Low permanent pressure loss, saving energy.

- Less maintenance and inspection required.

- Short length when compare to other flow meters.

- Wear and erosion are negligible.

- Available in numerous materials of construction.

Disadvantages and limitation

The practical drawbacks of Dall tube are- More Straight pipe used in the approach pipe length.

- Pressure differences so sensitive to upstream disturbances.

- Not suitable for hot feed water.

- Dall tube is designed for clean fluid; it is not appropriate for fluid having suspended solid particle.

Application

- Applicable to where a significant pressure drop is not tolerated. E.g. gas transmission pipeline

- Flow measurement in circular tubes.

Types of Dall tube

Dall tube differs in the method of construction to suit a particular application. The types are- Linear type Dall tube

- Contour Dall tube

- Dall short insert

- Dall long insert

- Sewage Dall tube

- Fabricated Dall tube