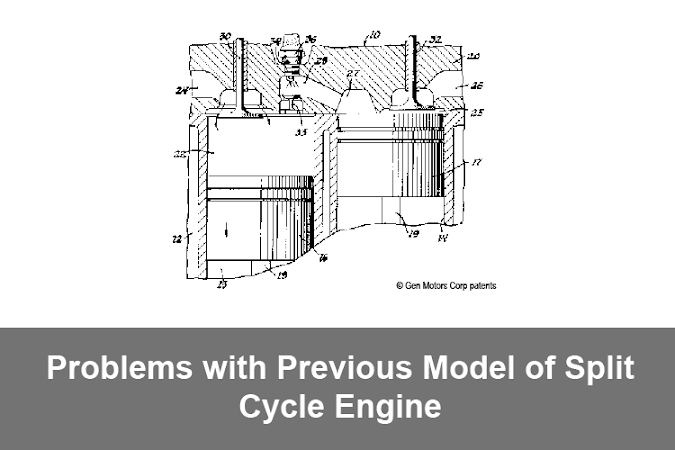

Problems with Previous Model of Split Cycle Engine

Earlier split cycle engine never matched the efficiency and performance of the conventional IC engine. The main challenges related to the previous split cycle engine are

- Poor breathing (low volumetric efficiency)

- Low thermal efficiency

Poor breathing (low volumetric efficiency)

Poor breathing problem arises when high-pressure gas trapped in the compression cylinder. This gas needed to re-expand before another fresh charge drawn into compression cylinder, effectively it reduces the engine capacity to draw air and resulting in poor volumetric efficiency.

Low thermal efficiency

The thermal efficiency older split cycle engine is worse than the conventional Otto engine. The primary reason for this is they all try to fire the air-fuel mixture before top dead centre. To fire before top dead centre the compressed air-fuel mixture in crossover passage allowed to expand into power cylinder as the piston in an upward stroke. By expanding of compressed air the work done on the air in compressor cylinder is lost, then it is recompressed as piston move to top dead centre.

By allowing compressed air to expand into power cylinder before the piston reaches the top dead centre, the engine needs to perform the work compression twice. Subsequently, it reduces the thermal efficiency of the engine

Read: How Scuderi engine solves poor breathing and thermal efficiency problem

Read: How Scuderi engine solves poor breathing and thermal efficiency problem