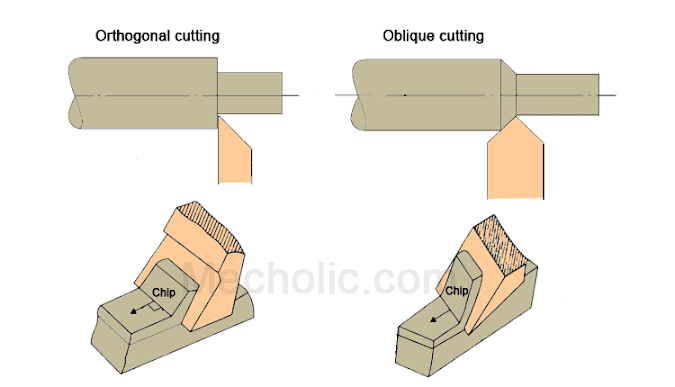

Orthogonal Cutting and Oblique Cutting

In a cutting process, the position of cutting edge of the tool with respect to the workpiece is important, based on which metal cutting process are classified into two categories.

- Orthogonal cutting

- Oblique cutting

Orthogonal cutting

In orthogonal cutting, the cutting edge inclination is zero and chip is expected to flow along the orthogonal plane. The cutting tool is presented to the workpiece in such a way that the cutting edge is normal to the tool feed direction. In orthogonal cutting, the radial force is zero, and it involves only two component of force; this simplifies the analysis of cutting motion.Oblique cutting

In oblique cutting, chip flow deviates from the orthogonal plane. Tool is presented to workpiece at an acute angle (θ < 90°) to the tool feed motion. The analysis of cutting include three mutually perpendicular component of force and it is being very difficult to analyses.Read: Difference between orthogonal and oblique cutting

Extra:

Orthogonal cutting also called two-dimensional cutting process. While the oblique cutting known as a three-dimensional cutting process.