Quick Comparison between NC and CNC

Read: What is Numerical control? Applications, Advantages, Limitation

What is CNC? Advantages, Limitations, Applications

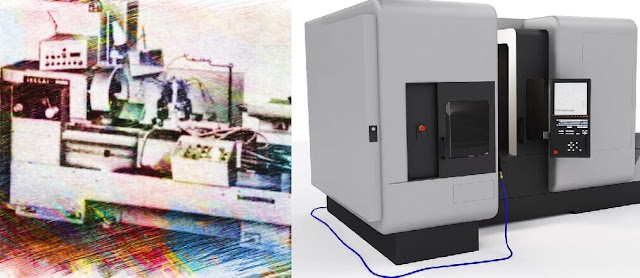

NC Numerical Control

|

CNC Computer Numerical Control

|

Punched tape/ part program need to load on the machine for each job.

It leads to tear and wear of punched tape.

|

Punched tape or programme instruction load once in the machine, then

it is stored in computer memory. This program is called from for each job.

That reduces the use of unreliable punched tape.

|

The problem of part program mistakes in punched tape

|

The ability to diagnose and debug the part program find

malfunctioning before the actual job is performed.

|

The program is not easily editable; the editing punched tape is

difficult. The whole process was slower.

|

The program can be edit immediately by using other input devices

(keyboard)

|

Limited flexibility

|

Greater flexibility, which provides easy opportunities to introduce

new control option. It also allows the conversion of the unit in the part

program (eg: inch to centimetre)

|

Low accuracy and productivity when compared to CNC.

|

High accuracy, productivity and repeatability.

|

Installation and maintenance cost is low

|

Installation and maintenance cost is high

|

No optimal speed and feed selection during machining.

|

CNC allows the changes in sped and feed. It is a total manufacturing

system.

|

It never favours the continues running.

|

CNC can run continuously 24x7.

|