Types of Orifice Plates - Advantages and Disadvantages (Concentric, Eccentric, Segmental, Quadrant Edge)

The orifice plate is one of the simplest devices that can be easily introduced to the flow system. It frequently used than any other flow meter. It acts as a primary device for measuring flow rate. This device works on the same principle as that of venturi meter. Orifice meter causes a significant amount of pressure drops compared to venturi. So orifice plates often used as restriction plates.

- Differential pressure flow meter working principle

- Venturi Meter – Aapplication, advantages, and disadvantages

Construction and design of Orifice Plates

The material for orifice is selected such a way that its sharp edges and surface are not deformed due to corrosion and erosion. This is a thin, flat circular plate with a circular hole concentric to the pipe; this is bolted to the flanges of two pipes. A square edged (90°) orifice can be used for measuring bidirectional flow. Orifice plate thicker than 3.175mm frequently beveled 45° at the downstream edge to facilitate smooth flow of fluid. The beveled orifice is, of course, unidirectional. Sometimes a drain or vent hole is provided where plates meet the pipe to avoid accumulation gas and air bubbles in the tube. A differential manometer is connected at both upstream and downstream side of the flow.Types of orifice plates

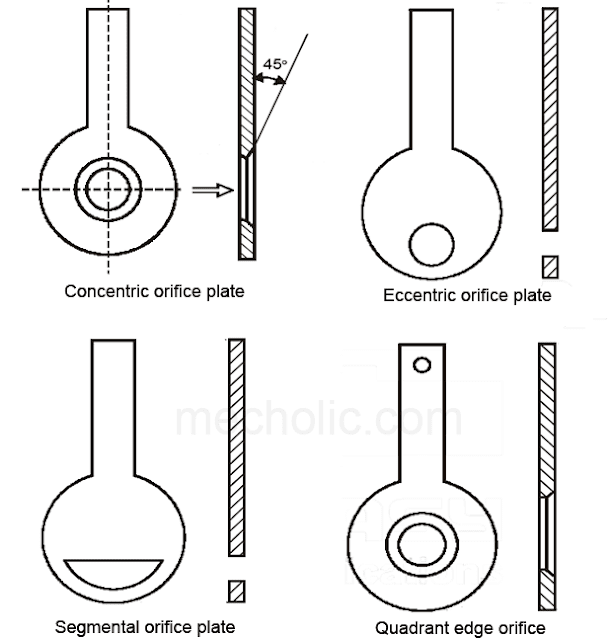

The typical designs of orifice plates are- Concentric orifice plate

- Eccentric orifice plate

- Segmental orifice plate

- Quadrant edge orifice plate

Concentric orifice plate

A concentric sharp edged orifice plate is the simplest and least expensive of the head meters. It is usually made of stainless steel. Other materials like nickel, Monel, etc. used when it is needed a good corrosive resistant property. The accuracy of these type orifice is very high.Eccentric orifice plate

It is similar to the concentric orifice plate except for the offset hole which is bored tangential to a circle. Location of the bore prevents accumulation of solid materials or foreign particles and makes it useful for measuring fluids containing suspended solid particles. The eccentric orifice is less accurate and has a high number of uncertainty when to compare to the concentric orifice plate. It is used when liquid consists of a large amount of gas dissolved in it.Segmental orifice plate

This is used for the same type of services as an eccentric orifice plate. It has a hole which is a segment of a circle. It is used with fluid containing more solid particles in it. They are more expensive than the eccentric orifice.Quadrant edge orifice plate

This type is used for flaws of dense fluid such as crudes, slurries, and viscous flows. Its edges are rounded to form a quarter circle. They are useful in the pipe have a low diameter (less than 2 inches). The drain hole is provided or located the bottom when gases are measured, to allow condensate to pass in order to prevent its building up at the Orifice plate. Similarly, a vent hole is located at the top when liquids are measured so that gases can pass and thus avoid gas pocket.Advantages and disadvantages of orifice plate

Advantages

- Simple in construction, the standards for construction and calibration are readily available.

- They are cheap; their price does not increase dramatically with size.

- Easy to install and remove.

- They are efficient and reliable for many years.

- Available in many materials.

- Easy to measure flow rate, because it produces the considerable pressure drop across the orifice.

- They can be used in a wide range of sizes.

- Their characteristics are well known and predictable.

Disadvantages

- Relatively high permanent pressure drop.

- Their characteristic may change due to erosion and corrosion.

- It may cause clogs in slurries. Not good with fluid having high viscosity.

- The fluid must be in single phase and homogeneous.

- Square root characteristics.

Coefficient of discharge of the orifice is about 0.6 - 0.75, and it causes loss of head about 60 - 70%