Eddy Current Clutch Working, Application, Advantages and Disadvantages

Eddy current clutches (or eddy current slip coupling) are available in a broad range of sizes and speed up to thousands of kilowatts in both vertical and horizontal configurations. They are an adjustable speed drive and provide soft starting capability. They are actually a slip control device. When starting eddy current clutch operates at 100% slip allow the driver (motor) to accelerate. When the motor reaches the full speed, the slip is decreased to the desired rate, providing engagement of the clutch.

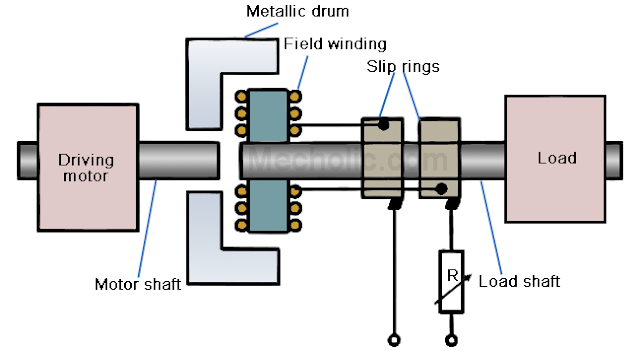

An eddy current clutch and an induction machine are identical in working principle. Fig shows an eddy current clutch. The input shaft directly coupled to the motor and variable speed output shaft is connected to load. A metallic drum is connected to driving shaft and field coil system is mounted on the output shaft. The slip rings used to excite the field system.

The load is initially at rest when the motor reaches the full speed; DC current is passed through the electromagnets. The resultant magnetic field produced an eddy current in the metallic drum. The magnetic flux produces a torque that brings the load to desired speed.

An eddy current clutch and an induction machine are identical in working principle. Fig shows an eddy current clutch. The input shaft directly coupled to the motor and variable speed output shaft is connected to load. A metallic drum is connected to driving shaft and field coil system is mounted on the output shaft. The slip rings used to excite the field system.

The load is initially at rest when the motor reaches the full speed; DC current is passed through the electromagnets. The resultant magnetic field produced an eddy current in the metallic drum. The magnetic flux produces a torque that brings the load to desired speed.

Advantages and disadvantages of Eddy current clutch

Since there is no contact required to power transmission, they are reliable and have a long life. The speed and torque can regulate by adjusting the DC. One advantage of eddy current clutch is that the smooth adjustment of both output torque and hence the speed control.The Eddy current clutch is usually tended to the small speed ratio (no more than10-30% speed reduction) due to consideration of efficiency and cooling. Careful design consideration must be given to providing adequate cooling of both field coil and metallic drum.

Application of Eddy current clutch

The Eddy current clutch is suitable where soft starting and speed control is required. They provide reliable speed control. They are typically used as a speed d reducer.- Electromagnetic clutch working, Applications, Advantages and disadvantages

- Magnetic particle clutch - Features and Applications