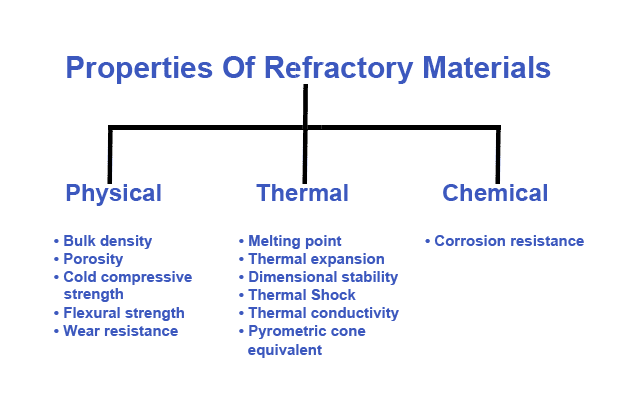

Physical, Thermal and Chemical Properties of Refractory Materials

Refractory materials are essential in various high-temperature applications, such as furnace linings, kiln linings, and incinerators. The quality and suitability of refractory materials for these applications depend on their physical, thermal, and chemical properties. The most common properties of the refractory material are listed below.

Physical properties

The refractory materials commonly characterized by their physical properties.

Bulk density

The bulk density of a refractory material is a general indication of its quality and is calculated as the ratio of its weight to its volume, measured in g/cm3. A higher bulk density indicates a more dense and compact material, which is typically stronger and has a better stability.Porosity

It is defined as the ratio of its pores volume to its total volume. A low porosity is desirable in refractory materials as it affects several other properties, such as resistance to abrasion and thermal conductivity. In general, a good refractory must have low porosity. Here are some advantages and disadvantages of high porosityAdvantages of high porosity

(i) Highly porous refractory have lower thermal conductivity. This is due to the presence of more air voids, which act as insulation and therefore, be used for lining furnaces.

(ii) High resistance to the thermal shock and heat spalling.

(iii) Pores act as a crack inhibitor.

Disadvantages of high porosity

(i) Reduces the strength.

(ii) Reduces the resistance to abrasion and corrosion.

(iii) Lower load bearing capacity.

Cold compressive strength

This indicates how refractory material can handle the load of installation or ability to withstand rigours transport, whereas the hot compressive strength shows how they will perform at high temperature. It is measured by a compression test. It is used to ensure that there is no crushing of refractory brick where it is subjected to high pressures.Flexural strength

Also known as the “bend strength.” The test consists of subjecting a concentrated central load on a specimen resting on two edges. The specimen is bent until it rapture and highest stress obtained during the test represents the flexural strength of the material.