What is Metal Drawing? Types Applications and Advantages

What is Drawing Manufacturing Process?

Drawing is a forming technique of pulling metal, glass or plastic materials through a die to extend and reduce their cross-sectional area. This deformation process uses tensile forces to elongate the workpiece. As a large cross-section workpiece passes through the die, it is plastically deformed, decreasing its width and thickness to create a thinner, longer product.

During drawing, the volume of the material remains constant, but the process causes an increase in length as the diameter decreases. This technique produces elongated profiles such as wires, rods, tubes, and other lengthy parts.

Requirement of Drawing Process

- The material should withstand high tensile stress.

- The material must possess enough ductility to withstand tensile stresses.

- The material should have a uniform composition, with no impurities or defects that could weaken the wire. This ensures the wire has consistent mechanical properties and behaves predictably during the drawing process.

- The material should have adequate strength to retain its shape after drawing.

- Resistance to work hardening: The material should not become excessively hard after repeated plastic deformation and cold working in wire drawing.

- The rod or wire must be thoroughly cleaned before being drawn to avoid imperfections.

- Lubrication should be applied to reduce frictional forces inherent in the drawing operations. A consistent and uniform lubricant layer is applied on the wire before each drawing pass.

Types of Metal Drawing Process

The metal drawing can be classified into the following three types:

Wire Drawing

The wire drawing process is used to create a circular, small diameter flexible rod, known as a wire, with specific tolerances. This process involves reducing the diameter of thick wire by passing it through a series of wire drawing dies, with each consecutive die having a smaller diameter than the previous one. The dies are typically made from materials such as cast iron, tungsten carbide, diamond, or other tool materials. It is important to note that the maximum reduction in the area of the wire is less than 45% in a single pass.

🔗Stages of Wire drawing process and Equipment used

🔗Applications and Advantages of Wire drawing process

Rod Drawing

Rod drawing is similar to wire drawing, except rods are rigid and larger in diameter than wires. This process requires heavier equipment than wire drawing because rods must be kept straight, whereas wire can be coiled. The workpiece is first fed into a die and pulled by a carriage to increase its length and decrease its cross-section. Finally, the rod is cut into sections for further use.

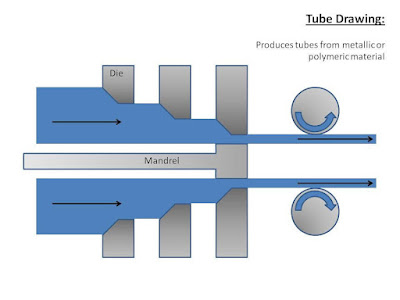

Tube Drawing

Tube drawing resembles rod drawing and wire drawing but uses a mandrel to decrease the wall thickness and diameter of tubes. This mandrel is positioned within a die, and its shape is reduced as the workpiece passes through by a carriage system. The tube may be circular or rectangular, and multiple passes are often needed to complete the drawing process.

Benefits and Applications of Metal Drawing

Metal drawing requires minimal tooling investment. As a result, the process is very affordable to operate. In addition to lower operational expenses, drawn metal parts can be lightweight yet retain high strength and durability.

Metal drawing is especially suited for generating cylindrical components such as wires, rods, tubes, etc. The process affords precise regulation of the wire gauge, making it well-suited for applications demanding precise tolerances.

Metal drawing benefits high-volume manufacturing through automation. Automated drawing equipment can operate continuously with minimal downtime and upkeep, enabling prolonged, high-output runs.

Advantages of Metal Drawing

One of the significant advantages of metal drawing is its ability to work with a wide range of metals. Manufacturers can use this process to draw metals such as alloys, aluminium, brass, bronze, cold-rolled steel, copper, iron, Kovar, molybdenum, nickel, silver, stainless steel, and titanium. Regardless of the material used, metal drawing offers several benefits over other metalworking methods, making it a popular choice among manufacturers.

Seamlessness: When parts or components are formed from a single blank, they are free of seams. This creates a more aesthetically pleasing finished product that is less likely to experience issues related to seam failure.

Rapid production and High production efficiency: Metal drawing can be an automated process, enabling the production of large quantities of products quickly and efficiently.

Stability of the parts: The metal drawing process can effectively minimize the risk of human error and ensure superior quality and stability of parts compared to those made manually.

Complex geometries: The multiple-step metal drawing technique can create intricate shapes with remarkable precision.

Reduced labour: With its capacity for high precision, automation, and fast production, metal drawing minimizes the amount of manual labour required by users.