What Is The Difference between Jig and Fixture?

Both jig and fixture are a supporting device used in mass production to reduce nonproductive time. They are an essential tool in both metal and wood working. They are not the same device, they entirely two separate tools with a different function. Although there are no much differences between them, the various aspects of them is described below.

What are the differences between jig and fixture?

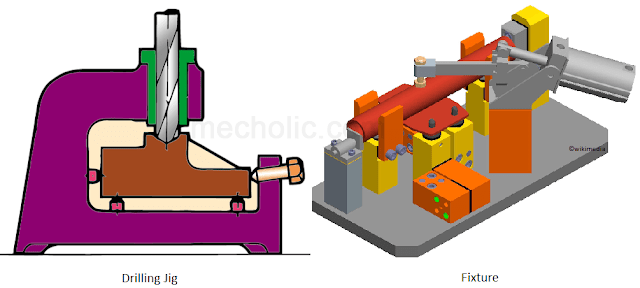

Jig is not only a work holding device, but it also provides some means of guidance for the cutting tools. It can use to control the motion and position of other instruments. Fixture is a device that used to locate and hold the component in position for a specific operation. Fixture secures the position of material during machining, but it does not guide any cutting tool during the machining.Accuracy, repeatability and interchangeability are the main objective of the jig. The objective of fixture is supporting of the component and ensure the component is stable during machining. For that reason fixture usually huge, heavier holding device, typically fastened to machine or the working table/surface.

Quick comparison between Jig and fixture

The key difference between jig and fixture is given below

Jig

|

Fixture

|

The main purpose is to control and guide the cutting tool.

|

The main purpose is to

hold and supporting of the component.

It does not guide the movement of the tool.

|

Main objectives are Accuracy, repeatability and

interchangeably

|

Main objective is to

reduce error by holding the component

in firmly on work table.

|

They

light when compared to fixture

|

Fixture

is usually rigid, bulky and heavy

|

Designing

of jig is complicated

|

Designing

of the fixture is not as much

complicated compared to a jig.

|

Typical application in drilling, tapping, reaming, counterboring, etc.

|

Typical application in planning, shaping, slotting,

milling, etc. It is also used for

assembling and inspection jobs.

|

During

machining, Jigs can hold in position simply by hand pressure.

They may be clamped to machine table

for heavier work.

|

Fixtures

are always rigidly fixed on machine table.

|

Read: What Are The Design Principles Of Jig And Fixture?

The latest advancement in production technology reduces the requirement of jig. The automation, CNC and DNC use digitally programmed data to define tool movement accurately, in such machining there is no importance to a guiding device.