Wilson-Hartnell Governor Construction and working

Construction and working of Wilson-Hartnell Governor

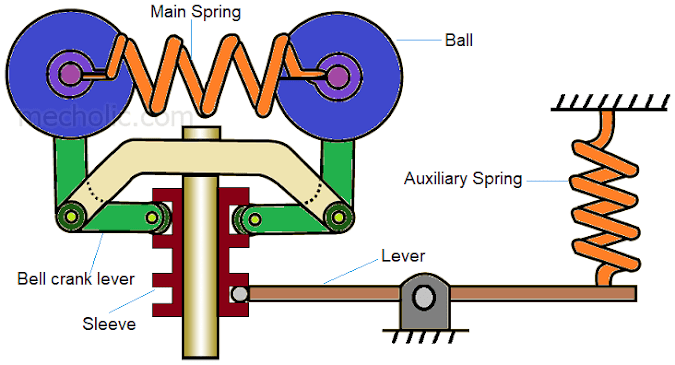

A Wilson-Hartnell Governor is shown in above figure. In this type of governor has a primary/ main spring and an auxiliary spring. The main spring arranged symmetrically on either side of the axis and it connects two flying balls on the vertical arms of bell crank lever. The horizontal arms of bell crank lever carry rollers which press against the sleeve of governor. An adjustable auxiliary spring is attached to sleeve mechanism of governor through a pivoted lever. The Purpose of this auxiliary spring is that to adjust the equilibrium speed for a given radius of rotation. The auxiliary spring tends to keep sleeve down.🔗 Hartung Governor construction and working

The bell crank lever rotates with the spindle. When the speed increases the radius rotation of ball increases. Outward movement of the ball actuate the bell crank lever and lift the governor sleeve. Upward movement of sleeve cause decrease in fuel supply and hence decrease the speed of engine. Similarly, when speed of spindle decreases, the balls tend to move inward. This results the downward movement of governor sleeve and the increase in fuel supply.

Figure shows a line diagram of Wilson-Hartnell Governor.

Here,

P = Tension in main spring

S = Tension in auxiliary spring

ka = Stiffness of auxiliary spring

kb = Stiffness of main spring

M = Mass of sleeve

m = Mass of each balls

Fc = Centrifugal force on a ball

r = Radius of ball rotation