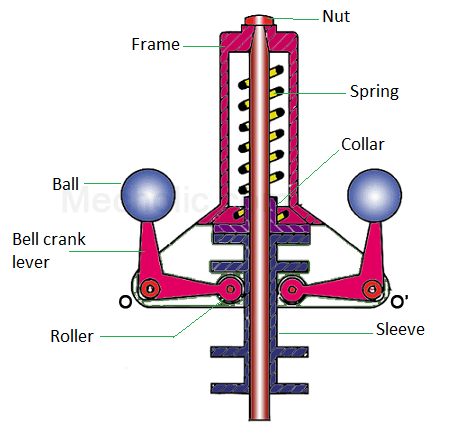

Hartnell Governor Construction, Working And Advantages

Hartnell governor construction and working

The sleeve moves up and down depending on the governor speed. When the speed of governor/ engine increase, the ball tends to fly outward from the axis of governor, but balls movement is constrained. The bell crank lever moves on pivot, roller end of lever lifts the sleeve upward against the spring force. This movement transferred to the throttle valve through the suitable mechanism, the result is a low fuel supply and decreasing speed.

When speed decreases the sleeve move downward, and throttle open to more fuel supply; which results in increasing speed.

- Comparison between Centrifugal and Inertia Governor

- Pneumatic Governor – Construction, Working, Advantages

- Watt Governor - Working, Types, Limitation

Advantages of Hartnell governor

- It can be operated at very high speed

- Smaller in size

- Very close regulation

- Pre-compression can be adjusted to give required equilibrium speed.

Read: Wilson-Hartnell Governor Construction and working